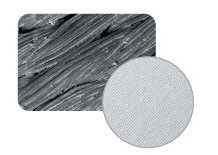

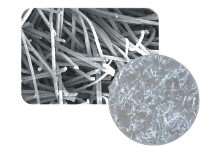

WOVEN

These cloths feature a cross-weave pattern, where abrasive particles embed and provide efficient material removal. They

feature low compression, applying effective pressure to the loose abrasive particles for maximum material removal and

flatness. This pattern is ideal for fine grinding, or coarse and intermediate polishing, and is more aggressive than nonwoven

cloths.

|

PLAN-Cloth |

Very hard, resin coated, durable, coarse-woven polyester for use with diamond

(30–6 μm). Produces high material removal rate and excellent flatness for fine

grinding, or coarse and intermediate polishing on a variety of materials. |

|

PLAN-B |

Very hard, resin coated, dense-woven polyester for use with diamond (15–3 μm).

Maintains superior edge retention and flatness and provides aggressive material

removal for coarse to intermediate polishing of metals, ceramics and refractory

materials. Not recommended for cold mounted materials. |

|

Gold Label |

Dense, uniquely woven nylon, extremely durable for use with diamond (15–3 μm).

Produces excellent flatness and provides a very high material removal rate on a

wide variety of materials. Exceptional for intermediate polishing. |

|

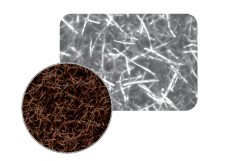

DiaMat |

Woven wool with a medium nap and low resilience for use with diamond (6–0.25 μm), colloidal suspensions or alumina. Provides very good edge retention and surface finish on a wide variety of materials including metals and polymers. |

|

Tech-Cloth |

Dense, woven, synthetic silk for use with diamond (9–1 μm). Produces very good

edge retention and provides excellent finish and flatness. Especially good for

coatings and samples composed of materials with varying hardness. |

|

White Label |

Very dense, woven, low-nap silk for use with diamond (6–0.25 μm). Provides

excellent flatness and edge retention prior to final polishing on a wide variety of

materials. Ideal for eliminating pullout in the final polishing steps. |

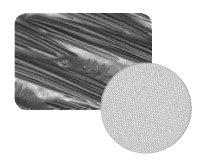

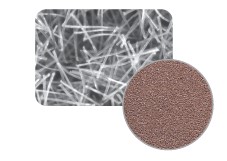

NON-WOVEN

Dense, woven, synthetic silk for use with diamond (9–1 μm). Produces very good edge retention and provides excellent finish and flatness. Especially good for coatings and samples composed of materials with varying hardness.

|

Kempad |

Non-woven, very low-nap textile for use with diamond (9–1 μm). Provides

good removal and flatness on a wide variety of materials. |

|

Pan-B |

Dense, non-woven, planarized textile for use with diamond (6–0.25 μm).

Provides good removal rates and edge retention on a wide variety of materials. |

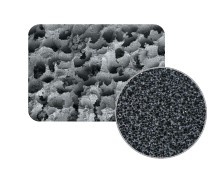

Chemo Textile

These cloths are engineered specifically for final polishing applications using alkaline, acidic or oxide polishing solutions.

|

Chem-Pol |

Dense, low-nap, porous polyurethane for chemical/mechanical polishing using

colloidal suspensions or alumina (1–0.02 μm). Long-lasting cloth provides an

excellent final polish for a wide variety of materials. |

|

Final A |

Highly dense, low-nap, porous polyurethane pad for use with colloidal suspensions or alumina (1–0.02 μm). This durable cloth is excellent for final polishing a wide variety of materials. Especially effective in eliminating smearing and pullout when preparing soft metals such as copper and aluminum, porous structures/materials or materials for SEM or TEM evaluation. |

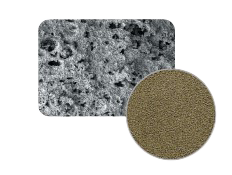

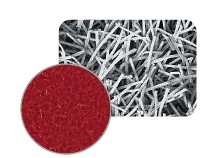

Flocked

These cloths, also known as “napped,” have various length fibers and fabric stiffness. They are mostly used for final polishing, as the fibers remove intermediate scratches. Firm fibers are commonly used for soft materials, while soft fibers are useful for hard materials.

|

Spec-Cloth |

Firm, medium-nap, synthetic rayon flock for use with diamond (1–0.25 μm) or

alumina. For general polishing of a wide range of materials. |

|

Vel-Cloth |

Soft, medium-/low-nap synthetic flock for use with diamond (1–0.25 μm) or

alumina. Provides very good flatness on a wide variety of materials. |

|

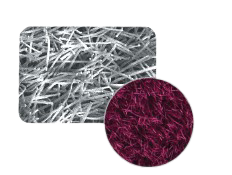

Red Final C |

Soft, dense, medium-nap, synthetic silk flock for use with diamond (3–0.25 μm),

colloidal suspensions or alumina to provide an excellent final polish on a wide

variety of materials. Especially effective when preparing electronic materials for

SEM or TEM evaluation. |

|

Final P |

Dense, low-nap, firm, synthetic flock for use with diamond (3–0.25 μm),

colloidal suspensions or alumina. Ideal for final polishing soft metals such as

copper, aluminum and solder. |

|

Final-POL |

Very durable, soft, low-nap, synthetic flock for use with diamond (3–0.25 μm),

colloidal suspensions or alumina. Excellent for final polishing ferrous metals and

composites. |

|

Final B |

Soft, low-nap, rayon flock for use with diamond (3–0.25 μm), colloidal suspensions

or alumina. Provides excellent finish and flatness, especially with hard materials,

ferrous metals and glass. |