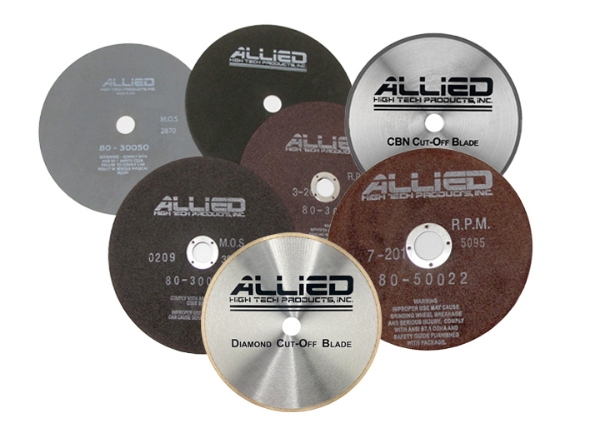

Blades

Cut-Off

These blades are specially engineered for laboratory sectioning. Aluminum oxide (Al2O3), silicon carbide (SiC), diamond and cubic boron nitride (CBN) abrasives are offered in various bond types for sectioning a wide variety of materials. Choosing the right blade for the right material is crucial in reducing thermal and structural deformation.

Protective metal arbor inserts are molded into resin bonded blades. Blade arbor holes fit both 32 mm and 1.25" spindle arbors. All blades are precision ground to slightly less than the stated diameter to universally fit all makes and models of cutting machines. Blotters are supplied to shield vibration from the metal flanges and help protect the blade from breaking during use. Blades designated with the letter "P" feature a special textured pattern and those with a letter "R" are fiber reinforced.

Mineral - Aluminum oxide is recommended for cutting ferrous metal alloys and silicon carbide is recommended for non-ferrous metal alloys. Diamond is best for hard, non-metal alloys. CBN is best for tool & die steels and other very hard/tough ferrous metal alloys.

Diameter - Select the blade diameter most appropriate for the saw, sample type and size.

Bond - Metal Bond blades provide longer life and durability than resin bond, but result in a coarser surface finish. Resin Bond blades cut cooler with less friction and minimal odor. Rubber Bond blades are available in thinner options and are ideal for environments where durability is desired.

Use the drop-down menus to refine your product search.

Scroll down to see available options.Precision Wafering

CBN Metal Bond - Recommended for low speed (<1,000 RPM) sectioning of ferrous metal alloys including steels, iron, cobalt, nickel and lead-based alloys. Resin Bond - Recommended for higher speed (>1,000 RPM) sectioning of ferrous metal alloys >50HRC/750 HV.

Diamond Metal Bond: High Concentration (HC) - Recommended for general laboratory sectioning, excluding ferrous alloys. Most commonly used at higher (>1,000 RPM) speeds. Low Concentration (LC) - Recommended for sectioning very hard or brittle materials such as ceramics, silicon, glass and refractories where chipping and pullout need to be minimized. Most commonly used at lower (<1,000 RPM) speeds.

Diamond Resin Bond - Recommended for cutting hard, brittle or delicate materials including ceramics, carbides, composites and exotic metals where low heat generation or improved surface finishes are desired. Most commonly used at higher (>1,000 RPM) speeds.

Aluminum oxide - Recommended for cutting ferrous metals and super alloys, while silicon carbide is best used for cutting non-ferrous metals and alloys. They produce minimal odor, cut cool and are suited for higher speed sectioning on non-gravity-fed saws. Two arbor sizes are offered.

Diameter - Diameter, thickness and arbor hole information can be found in the table below.

Bond - Bonded blades are composed of an inner metal core and an outer rim. The rim consists of either metal or resin mixed with abrasive, cured under high temperature and pressure to bond the matrix together. Metal bonding offers long life and durability, while resin bonding creates less heat and provides better surface finish. Metal bond blades work best for low speed sectioning (~1K and lower). For high speed sectioning (>1K RPM) resin bond, plated and solid core blades are recommended.

Type - Bonded blades feature an outer rim of (metal or resin) bonded abrasive to an inner metal core. Plated blades feature a single layer of coarse diamond on the outer rim of the metal core. Solid core blades feature an abrasive that is bonded solidly through to the arbor core.

Use the drop-down menus to refine your product search.