MILLING - X-Prep®

X-Prep®

The X-Prep® is a specialized 5-axis CNC-based milling/grinding/polishing machine designed to support electrical and physical failure analysis techniques and other applications requiring high precision sample preparation.

It features a wizard-based, user-friendly, intuitive interface that guides the operator through a screen sequence. As each screen appears, instruction is provided to the operator, ensuring every parameter and function is defined before operation. Help buttons on each screen provide access to additional explanation and instruction.

A high-definition (720p) color camera projects a magnified, razor-sharp image of the sample onto the touch screen to help the operator define the X/Y milling/grinding/polishing boundary.

Automatic tilt adjustment levels the sample plane parallel to the X/Y plane of the cutting tool. Unevenly mounted or tilted samples can easily be leveled using this functionality.

A variety of fixtures and accessories are available to accommodate various sample types and sizes. The X-Prep® is a specialized 5-axis CNC-based milling/grinding/polishing machine designed to support electrical and physical failure analysis techniques and other applications requiring high precision sample preparation.

X-Prep® Accessories

Each fixture is designed to accommodate a carrier insert onto which samples are mounted using wax. Wax offers an advantage over clamping when dealing with delicate samples, or for those so small that clamping is not an option. All fixtures allow the sample to be submerged in lubricant to maintain lower temperatures for improved tool life and sample preservation as well as capturing particulates from becoming airborne.

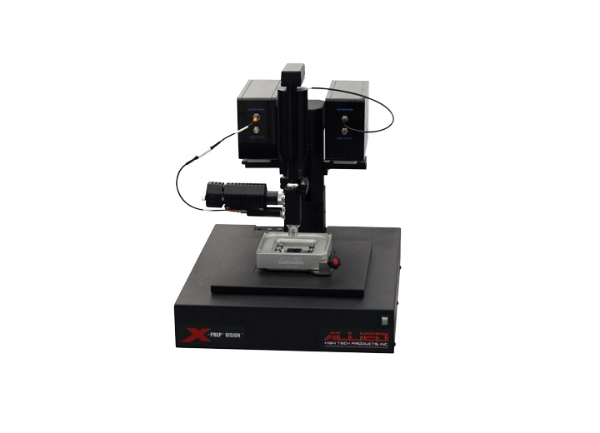

X-Prep® Vision™

The X-Prep® Vision™ is a metrology tool that enables measurement of silicon and semitransparent substrates. It is necessary for applications that require uniform thinning to a specific target with a tolerance of +/- 3 µm or better.

The X-Prep® fixture adapter is also secured to the motorized stage on the X-Prep® Vision™, ensuring the measurement/tool control coordinates remain aligned when transferred between systems.

A library with over 130 materials (i.e., GaAs, InGaAs, SiC, Sapphire/Al2O3, InP, SiGe, GaN, photo-resist) is included with every system.

Measurement & Observation - How it Works

IR light is focused onto a sample, and a unique signal based on the refractive index of the material is created. The return signal is analyzed by the software to produce a thickness value.

Measuring Below 10 µm Thickness

For applications requiring thinning to less than 10 µm, precise measurement is possible only by adding the visible light spectrometer accessory.

X-Prep® Vision™ Accessories

A variety of accessories are available as spares or replacements due to loss/breakage or general insurance.