Semi-automatic

MetPrep 3x™ & PH-3™

The MetPrep 3x™ grinding and polishing machines, with the PH™ line of power heads, are powerful systems for semiautomatic operation, ideal for low to high volume sample preparation requirements. Two combinations provide ideal solutions that accommodate any lab, application or material.

The microprocessor-based system allows the operator to use either the manual Input Mode to enter parameters throughout a procedure, or the user-defined preprogrammed Steps and Sequences Mode to select steps in a sequence as the procedure advances.

The PH-3™ power head offers maximum versatility for low to high volume semi-automatic sample preparation, using either central or individual sample force modes. The pneumatic-electric systems provide controlled sample force and allow up to nine (9) samples to be prepared simultaneously in central force and three (3) samples in individual force. The unique tilt-up design allows easy, unhindered access to the sample holder and platen, and eliminates the need to reposition the head during the preparation procedure.

MetPrep 3x™ & PH-4™

The MetPrep 3x™ grinding and polishing machines, with PH™ power heads, are powerful systems for semiautomatic operation, ideal for low to high volume sample preparation requirements. Two combinations provide ideal solutions that accommodate any lab, application or material. The microprocessor-based system allows the operator to use either the manual Input Mode to enter parameters throughout a procedure, or the user-defined preprogrammed Steps and Sequences Mode to select steps in a sequence as the procedure advances.

Either standard or magnetic 8"/203 mm or 10"/254 mm platens may be used with any adhesive, non-adhesive or magnetic system disc.

The PH-4™ power head offers maximum versatility for low to high volume semi-automatic sample preparation, using either central or individual sample force modes. The pneumatic-electric systems provide controlled sample force and allow up to nine (9) samples to be prepared simultaneously in central force and four (4) samples in individual force. The unique tilt-up design allows easy, unhindered access to the sample holder and platen, and eliminates the need to reposition the head during the preparation procedure.

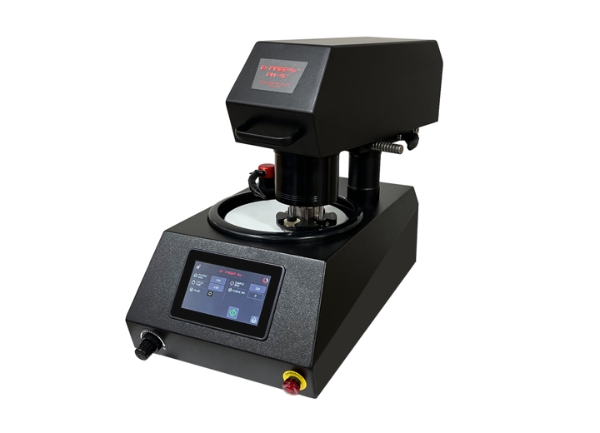

E-Prep 4x™ & PH-4i™

The E-Prep 4x™ grinding and polishing machine, with the PH-4i™ power head, is a simple yet powerful system for semiautomatic operation, ideal for low to medium volume sample preparation requirements. The user-friendly microprocessor-based system makes it easy to enter parameters and operate, and allows quick changes to sample force, cycle time, platen speed and sample speed.

Either standard or magnetic 8"/203 mm or 10"/254 mm platens may be used with any adhesive, non-adhesive or magnetic system disc.

The PH-4i™ power head offers excellent versatility for low to medium volume semiautomatic sample preparation, using individual force mode. The pneumatic-electric system provides controlled sample force and allows between one and four samples up to 2" (51 mm) diameter to be prepared simultaneously. The unique tilt-up design provides easy, unhindered access to the sample holder and platen, and eliminates the need to reposition the head during the preparation procedure.

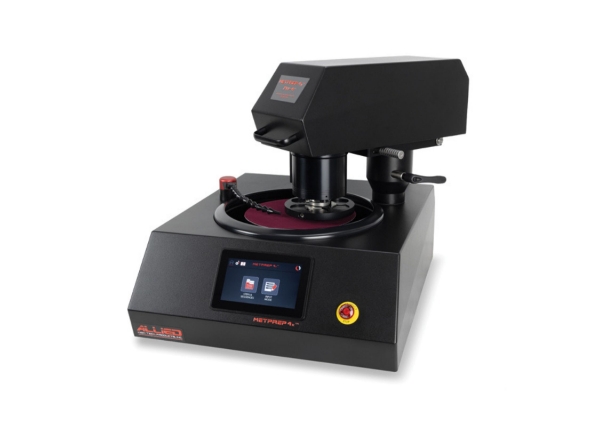

MetPrep 4x™ & PH-4™

The MetPrep 4x™ grinding and polishing machines, with the PH™ line of power heads, are powerful systems for semiautomatic operation, ideal for low to high volume sample preparation requirements. Two combinations provide ideal solutions that accommodate any lab, application or material.

The microprocessor-based system allows the operator to use either the manual Input Mode to enter parameters throughout a procedure, or the user-defined preprogrammed Steps and Sequences Mode to select steps in a sequence as the procedure advances.

The PH-4™ power head offers maximum versatility for low to high volume semi-automatic sample preparation, using either central or individual sample force modes. The pneumatic-electric systems provide controlled sample force and allow up to twelve (12) samples to be prepared simultaneously in central force and four (4) samples in individual force. The unique tilt-up design allows easy, unhindered access to the sample holder and platen, and eliminates the need to reposition the head during the preparation procedure.

Either standard or magnetic platens may be used with any plain/adhesive backed or magnetic system disc.

MetPrep 4x™ & PH-6™

The MetPrep 4x™ grinding and polishing machines, with PH™ power heads, are powerful systems for semiautomatic operation, ideal for low to high volume sample preparation requirements. Two combinations provide ideal solutions that accommodate any lab, application or material. The microprocessor-based system allows the operator to use either the manual Input Mode to enter parameters throughout a procedure, or the user-defined preprogrammed Steps and Sequences Mode to select steps in a sequence as the procedure advances.

Either standard or magnetic 10"/254 mm or 12"/305 mm platens may be used with any adhesive, non-adhesive or magnetic system disc.

ID-5x™

The ID-5x™ fluid dispenser provides automatic, unattended application of abrasive polishing solutions and lubricants. This five (5) position dispenser connects to the back of the MetPrep 3x™ and MetPrep 4x™ grinders/polishers, and is controlled and programmed through the touchscreen. Positions 4 and 5 feature high-speed pumps for dispensing colloidal solutions, and a magnetic stirring function for use with polishing slurries that normally settle.

The dispenser features a pivoting manifold mounted on the powerhead to position the dispensing nozzles so liquids clear the sample holder.

AD-5™

The AD-5™ fluid dispenser provides automatic, unattended application of abrasive polishing suspensions and lubricants. Its functions are programmed using the touchpad switches on its face plate, and activated through the MultiPrep™, and can also be used with ANY brand polishing machine as a standalone system. Timed, volume-controlled, variable frequency dispensing delivers reproducible results by eliminating inconsistencies between operators. This increases productivity and efficiency, while reducing consumables usage. Intuitive menu navigation and simple logic programming make the dispenser easy to use.

The AD-5™ features five (5) dispensing positions, two of which include a flush cycle to prevent clogging when using colloidal suspensions. Peristaltic pump technology offers mist-free drip delivery to the polishing surface.

PH Sample Holders

Individual force holders allow one or more samples to be prepared simultaneously. The advantage of individual preparation is that it allows removal of any number of samples from the grinding/polishing operation without affecting balance of the system. It is also ideal for applications where small geometry and site-specific cross-section requirements make alignment of more than three (3) samples to a common plane extremely challenging.

Fixed Diameter Mount Holders

Recommended for a specific mount diameter.

Variable Diameter Mount Holders

Recommended for multiple mount diameters. Utilizes spacer rings for specific diameter mounts that can be mixed or matched for maximum versatility.

The three (3) position holder is for the PH-3™ power head.

The four (4) position holder is for the PH-4™ power head.

The six (6) position holder is for the PH-6™ power head.

Rings are sold separately.

Central force holders secure mounts/samples on a common plane. A minimum of three (3) samples must be prepared at once for balance. Custom shapes and sizes are available.

Teardrop holders allow flexibility in the shape and size of the sample that can be held. A setscrew secures each sample.

Dual-cavity holders feature a single tightening point, which is useful for rapid insertion and removal of either one or two round or irregular shaped specimens per cavity.

Sample loading fixtures are used to set the sample protrusion from the holder at an equal distance for grinding/polishing to the same plane. Uniform, symmetric arrangement around the central drive adapter is necessary.