GRINDING

Grinding abrasives are available in several forms (belts, discs, rolls/sheets, stones and wheels), minerals (aluminum oxide, diamond, silicon carbide, zirconia alumina) and backings (adhesive, non-adhesive, ferromagnetic) from which to choose.

Silicon Carbide Discs

Use the drop-down menus to refine your product search.

Scroll down to see available options.Diamond Discs

Use the drop-down menus to refine your product search.

Scroll down to see available options.Zirconia Alumina Discs

Use the drop-down menus to refine your product search.

Scroll down to see available options.Belts

Belts are used for high-speed grinding of hard metals. Zirconia alumina is best for super alloys, aluminum oxide for ferrous metals and silicon carbide for general grinding applications.

Use the drop-down menus to refine your product search.

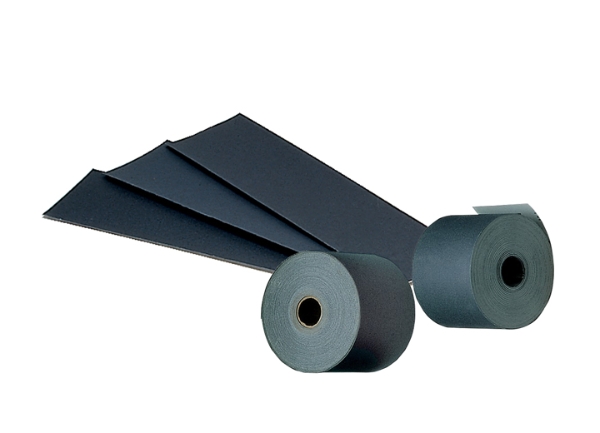

Scroll down to see available options.Rolls/Sheets/Strips

Rolls/sheets are used mostly for manual grinding applications on legacy machines.

Use the drop-down menus to refine your product search.

Scroll down to see available options.Stones

Allied's grinding wheels/grinding stones are made of silicon carbide or aluminum oxide. Silicon carbide is extremely hard but brittle. Aluminum oxide is slightly softer but is tougher than silicon carbide. It dulls more quickly, but it does not fracture easily therefore it is better suited for grinding materials of relatively high tensile strength.

Use Al₂O₃ for grinding ferrous metals and alloys. Silicon Carbide is recommended for grinding non-ferrous metals such as Titanium and Aluminum or when mixing non-ferrous and ferrous metals. Dimensions listed are diameter x thickness x arbor hole.

Use the drop-down menus to refine your product search.

Scroll down to see available options.Platen Accessories

Standard Platens are precision lapped parallel, then hard anodized for maximum wear resistance. They are used with adhesive backed discs, double sided adhesive discs and disc holding bands, or when converting to a magnetic platen using magnetic bases.

Magnetic Platens combine a standard aluminum platen with a cross-hatched magnetic surface for maximum flatness and adherence. Only one platen is needed throughout the grinding and polishing process, allowing all magnetic system cloths/abrasive discs or ferromagnetic discs to be utilized.

Disc holding bands are made of anodized aluminum and secure plain back discs to a standard platen. A protrusion around the top of the band allows variable sized discs (± 3 mm) to be secured.

Use the drop-down menus to refine your product search.