Quality Products for Metallographic Sample Preparation & Analysis

Contact Us 1.800.675.1118

- Home /

- Epoxy

Epoxy

|

Epoxy resins offer superior adhesion, feature low viscosity, allowing it to penetrate porous and open structures and offers superior chemical resistance. They consist of a resin and hardener that are measured by weight, then thoroughly mixed to produce a homogeneous mixture before pouring into a mold cup. Once poured, they can be subjected to vacuum (~ 20-25 mm Hg/2.6 - 3.3 kPa) help draw it into porous, open structures and remove any air bubbles, then left to cure at room (~ 25 °C) temperature. Epoxy resins are compatible with most all mold cups and a mold release is recommended to make it easy to extract the cured/hardened mold from the cup. |

|

|

EpoxySet - Curing in 8-hours at room temperature, this extremely low viscosity resin (300 cP) is crystal-clear (ref. index 1.51) offering superior adhesion and hardness (89 shore D) with a low exothermic temperature of 54 °C/130 °F. Resin/hardener weight mixing ratio - 100:12. |

|

| EpoxyMount - Curing in 2-hours @ room temperature, this clear resin offers excellent hardness (87 shore D) and clarity (ref. index 1.51) with a peak exothermic temperature of 66 °C/150 °F. Resin/hardener weight mixing ratio - 10:3. |  |

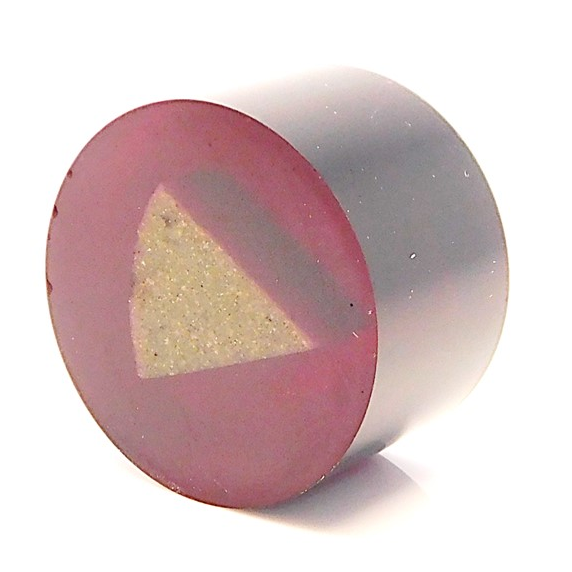

| EpoRed - A red-dyed resin for use with EpoxySet hardener, this produce produces a red tinted translucent mount that offers contrast in darkfield illumination in an optical microscope. |  |

SUPPORT

EQUIPMENT

CONSUMABLES

INDUSTRIES

EMAIL SIGN UP

Sign up to receive the latest info on new ALLIED products, special offers and more.

By signing up you agree to receive emails from Allied High Tech Products,inc. With new Product announcments,special offers and more.You can unsubscribe at any time. See our Privacy Policy or Contact Us by filling out this form,emailing at info@alliedhightech.com