Products tagged with 'x-prep accessory'

4-Flute

A variety of end mills are offered and optimized for general material categories, designated in their description and described here.

Al/Cu tools (silver) are ideal for cutting aluminum (Al) or copper (Cu) dry.

Fe tools feature a coating (dark brown) suitable for either wet or dry cutting of a wider variety of metals, including ferrous (Fe) alloys.

PCB tools are diamond coated (very dark) for durability and suitable for wet (submerged in fluid) cutting printed circuit board (FR4/PCB) substrates with less than 50% glass content.

For further details, including recommended operation conditions, please refer to the product guide titled “X-Prep Milling/Polishing Tools”.

Use the drop-down menu to refine your product search.

Diamond Tools

Bonded diamond tools are used for high precision grinding of a variety of materials, including silicon, sapphire, SiC and other non-metal alloys. They feature a beveled tip geometry to facilitate grinding which can be quickly reshaped to extend tool life.

- Metal bond for general use and long life

- Resin bond for brittle materials (SiC) and improved finish

Plated diamond tools are available in a fine and coarse grade and are used for higher removal rate than bonded diamond tools and result in a rougher finish that may require cleanup operations using a bonded tool before polishing. They are an excellent choice for rapid removal of high glass content FR4 substrates.

Use the drop-down menus to refine your product search.

Mount

Mounts are used in conjunction with grinding discs or polishing pads/discs that are secured to the end using high performance, instant adhesives. They are all 38 mm in length with a 3 mm diameter shank for use with the X-Prep®.

Ruby Tip

This leveling probe consists of a collet adapter and ruby (ball) tip (1 mm) stylus. The stylus can be threaded out of the adapter and replaced as needed. Slide a tool into the cross-hole to loosen and/or tighten the stylus into the collet adapter.

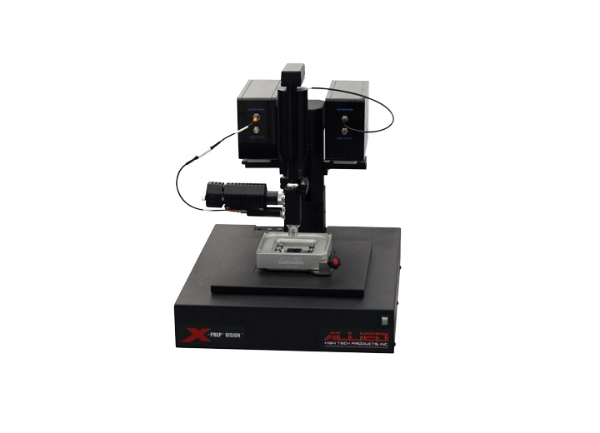

X-Prep® Vision™

The X-Prep® Vision™ is a metrology tool that enables measurement of silicon and semitransparent substrates. It is necessary for applications that require uniform thinning to a specific target with a tolerance of +/- 3 µm or better.

The X-Prep® fixture adapter is also secured to the motorized stage on the X-Prep® Vision™, ensuring the measurement/tool control coordinates remain aligned when transferred between systems.

A library with over 130 materials (i.e., GaAs, InGaAs, SiC, Sapphire/Al2O3, InP, SiGe, GaN, photo-resist) is included with every system.

Measurement & Observation - How it Works

IR light is focused onto a sample, and a unique signal based on the refractive index of the material is created. The return signal is analyzed by the software to produce a thickness value.

Measuring Below 10 µm Thickness

For applications requiring thinning to less than 10 µm, precise measurement is possible only by adding the visible light spectrometer accessory.