Products tagged with ''

Belts

Belts are used for high-speed grinding of hard metals. Zirconia alumina is best for super alloys, aluminum oxide for ferrous metals and silicon carbide for general grinding applications.

Use the drop-down menus to refine your product search.

Scroll down to see available options.Lubricants

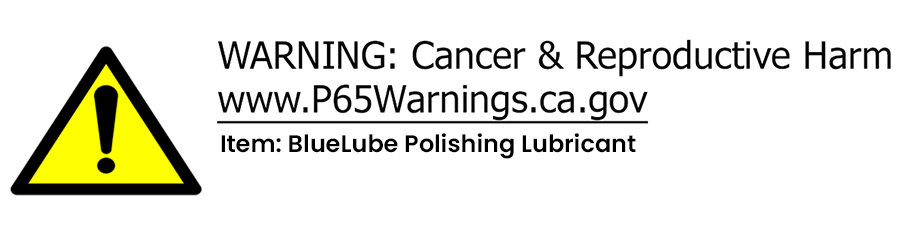

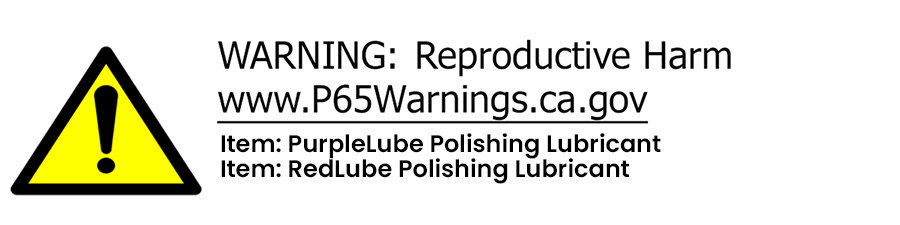

Lubricants enhance the polishing performance of diamond suspensions, compounds, and lapping films to by reducing friction, helping to increase and extend product efficiency.

They are used in conjunction with compound, suspension(s), slurries and as an alternative to water on lapping films. They reduce friction and extend the life of the cloth and abrasive by keeping the surface wet and cooled.

All 16 and 32 oz. bottles are supplied with both a trigger sprayer and flip-top for manual dispensing. Gallon containers are supplied with an empty, prelabeled 16 oz. empty bottle for convenience.

Note: Shipping restrictions apply to some of these products and are considered "DG" by IATA and US DOT, additional charges may apply/be incurred.

Use the drop-down menus to refine your product search.

Platen Accessories

Standard Platens are precision lapped parallel, then hard anodized for maximum wear resistance. They are used with adhesive backed discs, double sided adhesive discs and disc holding bands, or when converting to a magnetic platen using magnetic bases.

Magnetic Platens combine a standard aluminum platen with a cross-hatched magnetic surface for maximum flatness and adherence. Only one platen is needed throughout the grinding and polishing process, allowing all magnetic system cloths/abrasive discs or ferromagnetic discs to be utilized.

Disc holding bands are made of anodized aluminum and secure plain back discs to a standard platen. A protrusion around the top of the band allows variable sized discs (± 3 mm) to be secured.

Use the drop-down menus to refine your product search.

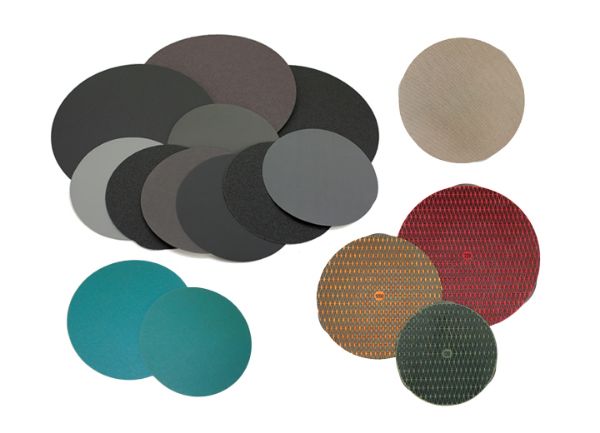

Discs

Summary of all discs goes here.

Use the drop-down menus to refine your product search.

Scroll down to see available options.Diamond Grinding Discs

These durable, film-backed diamond abrasive discs are used as an alternative to bonded diamond tools for high MRR - material removal rates. Available in different grades from coarse to very fine, color coding helps with visual identification, each has its own effective range of material removal indicated on this page below the table.

Discs are secured to mounts using a high-performance adhesive like LOCTITE® 460™ or 454™, and peel off easily when worn.

Discs

Standard Diamond Lapping Film consists of precision graded diamond particles resin bonded to a uniform mylar film. They provide excellent edge retention and maintain coplanarity regardless of varying materials or hardness within the sample. Typically used for unencapsulated cross-sectioning, TEM wedge/plan-view polishing, backside polishing and FIB sample thinning.

NOTE: Quantity discount pricing is available for this product. Ordering quantities of 5-9 packs and 10+ packs will automatically trigger a discount in the shopping cart.

Use the drop-down menus to refine your product search.